Search...

100% Polyester Printed Fabrics are widely used in clothing, home textiles, advertising flags, stage scenery, outdoor products and other fields due to their excellent durability, wrinkle resistance and color expression. With the development of textile technology and digital printing technology, the functionality and visual effects of polyester fabrics have been greatly improved. However, in order to give full play to its advantages in practical applications, scientific planning must be carried out in terms of material selection, design, processing and purpose adaptation.

In the material selection stage, the required fabric specifications should be clarified according to the usage scenario. There are many types of 100% polyester fabrics, such as high-density Oxford, chiffon, georgette, four-way stretch, etc. Different weaving methods determine the feel, breathability and elasticity of the fabric. For example, when used for outdoor flags or banners, high-strength, UV-resistant high-density polyester should be selected; while for women's clothing or dresses, light and soft polyester chiffon or elastic knitted fabrics are more suitable. In addition, attention should be paid to the fabric's gram weight (gsm), warp and weft density, and whether it has been treated with functions such as waterproofing, anti-static, and breathability.

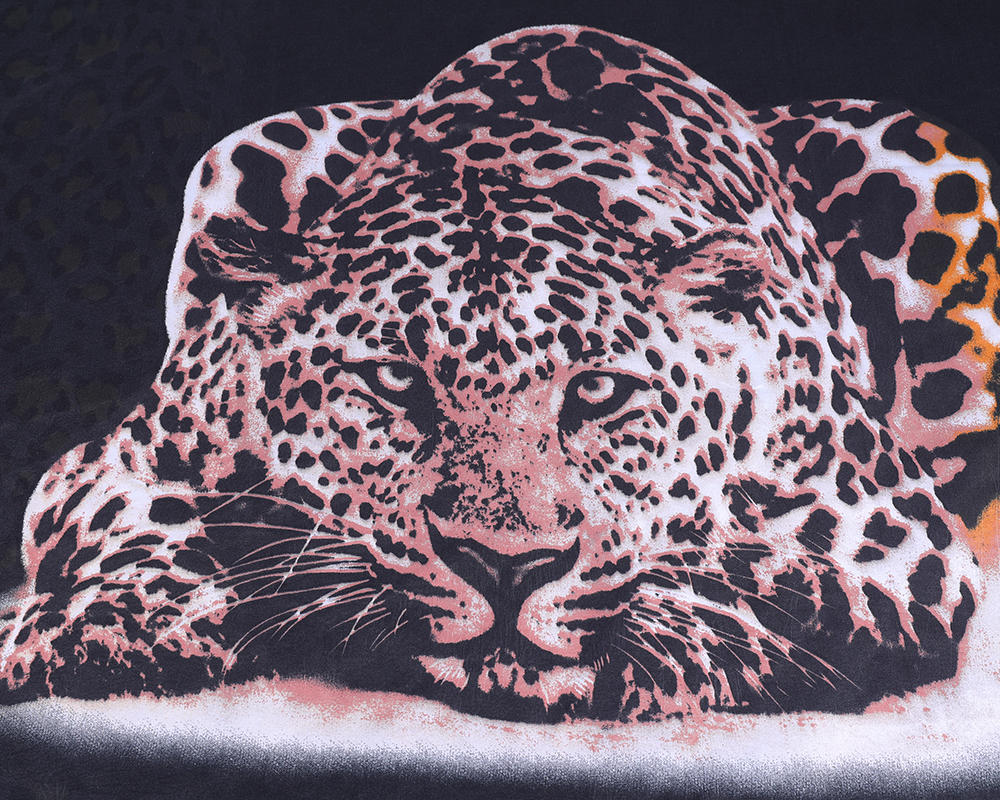

In the selection of printing technology, it is necessary to make a reasonable judgment based on the pattern requirements and environmental protection standards. At present, common printing methods include thermal transfer, digital direct printing and reactive printing. Thermal transfer is suitable for small batch customization, with bright colors and clear details; digital direct printing is suitable for large-scale production, supports gradient colors and complex patterns, and is more environmentally friendly; while reactive printing has natural colors and good feel, but the cost is higher. It is recommended to use non-toxic and environmentally friendly dyes, and ensure that the finished products pass relevant quality tests (such as color fastness and washability tests) to meet the requirements of export or high-end markets.

In terms of functional improvement, more additional properties can be given to fabrics through post-finishing technology. For example, adding anti-UV coating can enhance sun protection; adding antibacterial agents can improve hygiene and safety; using three-proof (waterproof, oil-proof, and anti-fouling) treatment can expand its application in the field of outdoor or functional clothing. For products that need to be washed frequently, such as hotel bedding, uniforms or sportswear, it is recommended to choose polyester fabrics with wrinkle resistance and quick drying properties to improve practical value and service life.

Reasonable matching and use in application scenarios are also crucial. In the clothing industry, polyester printed fabrics are often used to make T-shirts, dresses, sportswear, etc., and are particularly suitable for showing bright patterns and personalized styles; in the field of home textiles, they can be used for decorative products such as curtains, sofa covers, cushions, etc., and their good color fastness and anti-fading properties ensure long-term beauty; and in commercial displays, festival layouts and other occasions, polyester fabrics are easy to cut, print and reuse, making them ideal visual communication carriers.

Under the trend of environmental protection and sustainable development, more and more brands are paying attention to the recycling and carbon footprint control of fabrics. Although traditional polyester is a petroleum-based synthetic fiber, recycled polyester (rPET) has gradually emerged in recent years. Its performance is comparable to or even better than that of virgin polyester and has been widely used in many industries. Therefore, while pursuing high quality, we should also consider the use of environmentally friendly polyester fabrics to promote the construction of a green supply chain.

To achieve the high quality and multifunctional application of 100% polyester printed fabrics, it is necessary to comprehensively consider multiple dimensions such as material properties, printing technology, functional processing, applicable scenarios and sustainable development. Only under the premise of scientific material selection, fine processing and rational use can the powerful performance of polyester fabrics be truly brought into play to meet the increasingly diversified and high-standard market demands.

English

English

中文简体

中文简体

Español

Español

.jpg?imageView2/2/format/jp2)