Search...

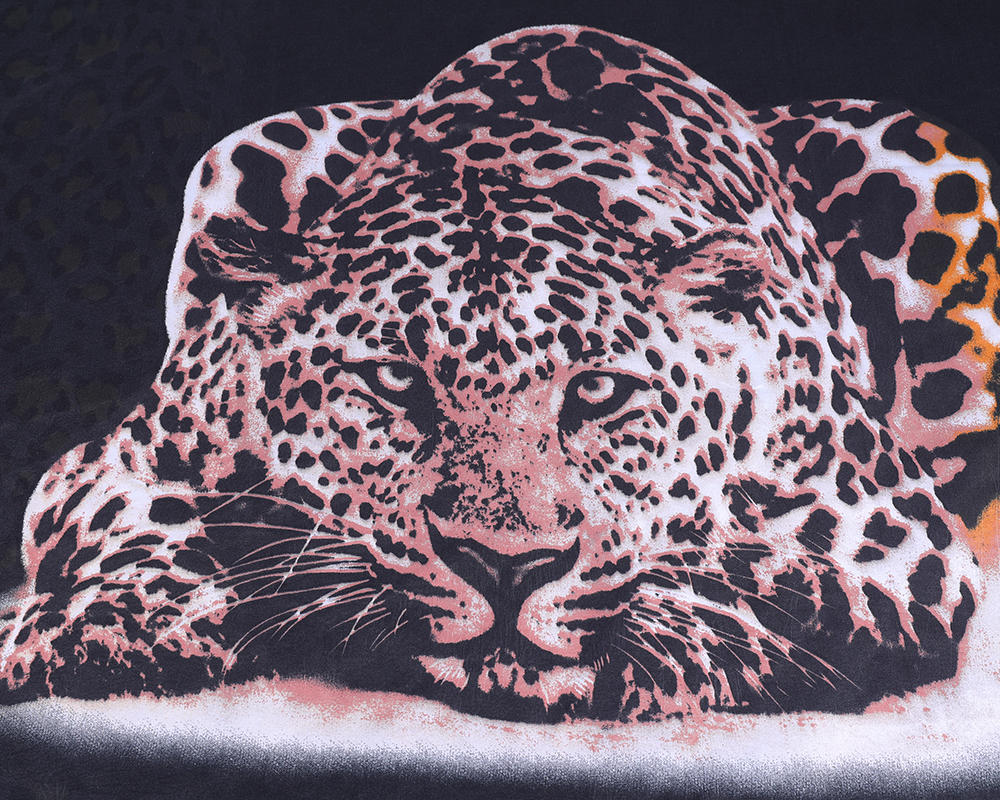

Maintaining the color and pattern stability of Printed Ultrasonic Fabric, especially under long-term use and exposure to different environmental conditions, is the key to ensuring its quality and long-lasting appearance. Since this fabric involves both printing and ultrasonic welding processes, it is necessary to consider many factors to optimize the stability of color and pattern. Here are some methods and techniques to ensure that the color and pattern can remain stable under various conditions of use:

1. Choose high-quality inks

UV-curable inks: UV-curable inks can quickly cure and form a solid coating after printing, enhancing the weather resistance and UV resistance of the ink and reducing the possibility of fading. UV inks are suitable for outdoor applications because they can resist ultraviolet rays in sunlight and reduce fading or discoloration caused by ultraviolet rays.

Water-based inks: Water-based inks are more environmentally friendly, suitable for milder environments, and have better color vividness, but their durability and UV resistance are weaker, and they are suitable for indoor use.

Solvent-based inks: This type of ink usually has strong weather resistance and is suitable for long-term exposure to outdoor environments. They perform well in water resistance and weather resistance, and can effectively prolong the stability of color.

2. Optimize the printing process

Multi-layer printing: By using multi-layer printing, you can ensure that the colors are fuller and brighter, and increase the coverage of the pattern. Especially when doing complex patterns or gradient color effects, multi-layer printing helps to maintain the layering and depth of the color.

Thermal transfer technology: For fabrics with complex patterns or that require high color stability, thermal transfer technology can be used. This technology can firmly transfer the color to the surface of the fabric, thereby reducing the impact of factors such as friction and washing on the color.

Accurately control printing parameters: During the printing process, accurately controlling parameters such as ink thickness, temperature, pressure and printing speed helps to maintain color uniformity and stability. Too thick an ink layer may cause the color to fall off or fade, while too thin an ink layer may cause the pattern to be unclear or faded.

3. Surface treatment and pretreatment

Anti-UV coating: Adding an anti-UV coating to the fabric can effectively improve the light resistance of the fabric and prevent color fading caused by ultraviolet rays. Common anti-UV coatings include polyurethane coatings and polyester coatings, which can protect the fabric while enhancing the stability of the pattern.

Waterproof coating: Adding a waterproof coating to the surface of the fabric can not only improve the waterproof performance of the fabric, but also effectively protect the printed pattern and prevent water from dissolving or penetrating the ink. The waterproof coating prevents the pattern of the fabric from being damaged in a humid environment.

Anti-fouling coating: Adding an anti-fouling coating to the fabric can reduce the adhesion of pollutants such as oil and dust, and maintain the clarity of the printed pattern. Especially for products that need to keep the visual effect clean (such as advertisements, exhibition cloth, etc.), the anti-fouling coating can effectively prolong the cleanliness and brightness of the pattern.

4. Use a thermally stable ultrasonic welding process

Temperature and pressure control: When performing ultrasonic welding, it is crucial to control the temperature and pressure of the welding. Excessive temperature may affect the stability of the printed pattern and cause the ink to fade or deform. Therefore, during the welding process, the parameters of the ultrasonic welding machine should be precisely controlled to ensure the compatibility between the welding point and the printed pattern.

Cooling time: Make sure that the cooling time after welding is long enough to avoid shrinkage or shedding of the surface ink due to too fast cooling, thereby affecting the stability of the color.

5. Post-treatment and curing

Drying and curing: Dry and cure the printed ultrasonic fabric to ensure that the ink is firmly attached to the fabric surface. Especially for solvent-based inks and UV inks, the curing process can improve their durability and anti-fading ability.

Heat setting: Through heat setting treatment, the fabric can be set and fixed at a certain temperature. The pattern and color are prevented from being deformed due to stretching or friction during daily use.

Surface sealing: Sealing the surface of the printed fabric (such as coating a transparent protective layer) can further increase the stability and durability of the color and prevent the pattern from being damaged by external factors (such as moisture, ultraviolet rays, friction).

6. Choose the right base fabric (fabric)

The choice of base fabric is crucial to the stability of the printed pattern. The selection of suitable fiber types (such as polyester, nylon, polyester, blended fibers, etc.) can ensure that the printed pattern has strong adhesion to the fabric and is not easy to fall off or fade. Polyester fabrics usually have good printability and color stability.

Density and fabric structure: The density and structure of the fabric will also affect the color retention. The tight fabric structure helps to better fix the ink and prevent the color from falling off due to friction or sunlight.

7. Washing and care recommendations

In the care of printed ultrasonic fabrics, use low-temperature water washing and mild detergents to avoid damage to the pattern by high temperature and strong chemicals. In addition, avoid strong friction or use of overly strong detergents, which will affect the stability of the printed pattern.

Avoid long-term exposure to sunlight: Although UV resistance can be increased by ink and coating, long-term exposure to sunlight will still accelerate color fading. For printed fabrics used outdoors, consider turning them over regularly or using sunshade equipment.

8. Anti-oxidation and weathering resistance enhancement

For printed ultrasonic fabrics used outdoors, the stability of patterns and colors can be further improved through chemical treatments that enhance anti-oxidation and weathering resistance. These treatments can reduce the erosion of fabrics by ultraviolet rays, oxygen and moisture in sunlight and extend their service life.

Maintaining the color and pattern stability of Printed Ultrasonic Fabric requires multi-faceted efforts to ensure the coordination of material selection, printing process, welding process and post-processing methods. By selecting high-quality inks, optimizing printing and welding processes, and applying anti-UV and waterproof coatings, the printed patterns can be effectively prevented from fading, damaging or distorting, thereby ensuring the stability of the appearance and functionality of the fabric in long-term use.

English

English

中文简体

中文简体

Español

Español

.jpg?imageView2/2/format/jp2)